|

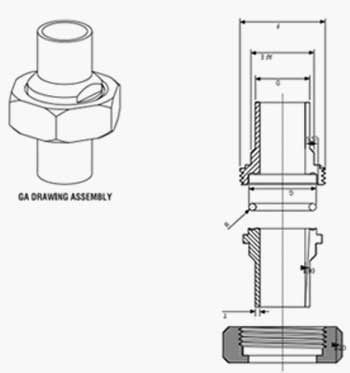

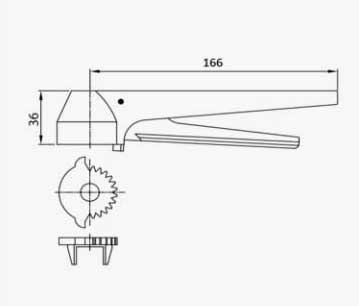

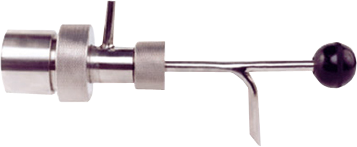

SMB X-Flow sampling valve provides inline sampling of free flowing and non free flowing materials (granules,powders,flakes, powdered milk and pharmaceutical products in gravity chutes and hoppers. Scoop provided can be pushed inside and can be pulled outside with sample then turned 180 degree using the handle to take the sample in a bottle/ flask

Valve Body : Stainless steel AISI 316L

(welding parts with material certificate)

Sealing : Silicone EPDM on request

Product Pressure : Max.4bar (65PSI) as standard 6 bar is available on request.

Technical Data |

||

Max operating |

: |

150 �C |

CMax.operating pressure |

: |

6bar |

Material-parts in contact with medium |

: |

316l |

-o-ring |

: |

EPDM |

Details For Ordering |

||

Sapmling valve Dn25 |

: |

20101 |

with steam diaphragm valve |

: |

20102 |

with sterile cartridge |

: |

20103 |

with stem diaphragm valve and sterile cartridge

|

: |

20104 |

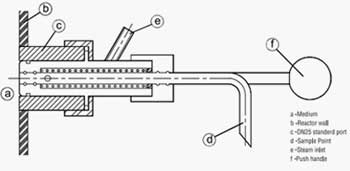

Mounting : On tanks and pipe workNormally the valve should be mounted horizon-tally with one outlet in upward position and onein downward. If the valve is mounted in anotherposition if should be seared that complete drain-age can take place from one of the outlets. |

||

| Benefits | Spare Part List : Part No | Oprating Information (Example) |

| Sterilisable in place with alcohol or steam |

2001 :0'rings |

Model :Type P-KT-01 |

Representative sampling, giving repeatable results |

2002 :SS 316 springs |

Application : Fermented broth |

Safe tosecondary contamination |

2003 :SS316L fixing Nut |

Size: DN25 |

Dual purpose, bulk and micro samples (special version) |

2004 : 25mm DN port nut |

Type of mounting Socket |

Manual and User-Friendly |

2005 8mm OD sampling tune |

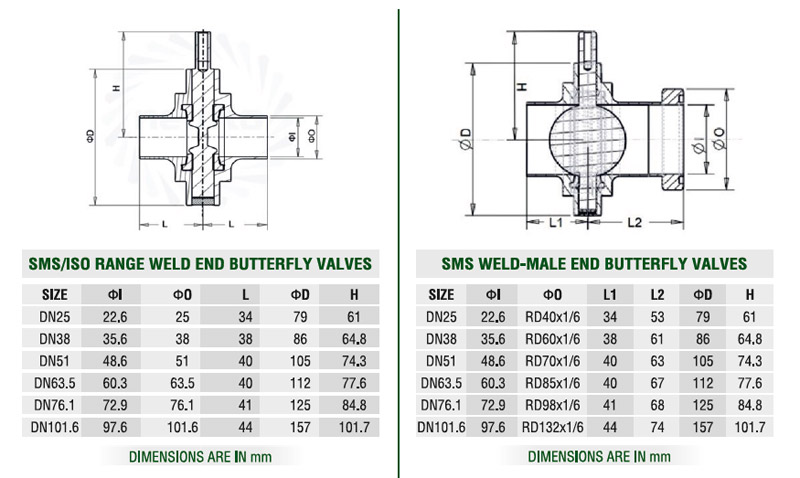

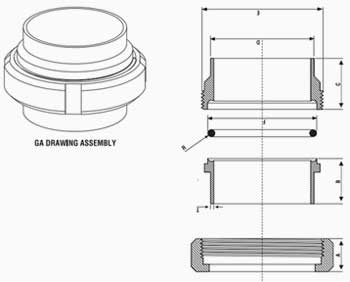

| Sr. No | Model Name | A | B | C | D | E | F | R | T |

| 1 | DN 63.5 | 17 | 27 | 29.4 | 75 | 63.5 | 68 | 1.5 | 2.1 |

| 2 | DN 76 | 20.1 | 33.3 | 30 | 87.4 | 76 | 78 | 1.5 | 2 | ALL DIMENSIONS ARE IN MM |

| Sr. No | Model Name | A | B | C | D | E | F | G | RT |

| 1 | DN 8 | 12.1 | 27.4 | 28.1 | 8 | 17 | 21.8 | 15 | 1.41.6 |

| 2 | DN 12.7 | 12.1 | 27 | 28 | 12.7 | 17 | 21.8 | 15 | 1.251.6 |

| 3 | DN 19 | 12.6 | 27.3 | 28.5 | 19 | 22 | 29.75 | 23.5 | 1.251.66 |