SM Biosystems

We are a trusted name in Project Engineering and Process Automation including design, engineering, supply of equipment and its installation, testing and commissioning of projects and also execute projects on turn key basis for the dairy, starch, food and beverage, distillery, brewery, pharmaceutical, refrigeration and chemical industries.

...Read more

|

Puriflux - DMW / Purified Water / WFI Distribution Systems

|

|

|

Puriflux - DMW / Purified Water / WFI Distribution Systems

We are Manufacturer, Supplier, Exporter of Puriflux- DMW / Purified Water / WFI Distribution Systems, Purified Water, Water for Injection Systems, Water for Injection Distribution Systems and our setup is situated in Pune, Maharashtra, India.

Description & Applications

Description & Applications

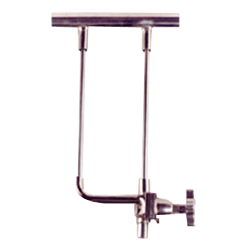

PURIFLUX enables consumption of Water-for-injection / Purified / Distilled water with continuous flow of water at the consumption point as per cGMP norms. PURIFLUX fitting is specially designed to be welded in the main loop. This is to avoid running main loop up to the point of use and to avoid using bigger valves. The unwanted dead legs are avoided. This system is terminated at consumption point using specially fabricated 3 way SS316L body diaphragm valve.

Features

• Designed as per cGMP norms, Hygienic

• MOC SS316L, electropolished

• Main loop not required to run up to consumption point.

• Various sizes available as per consumption.

• No welded parts

• Cost efficient

Puriflux - DMW / Purified Water / WFI Distribution Systems